Before starting to calculate the feed rate for tapping, feed rate for milling feed rate for CNC milling, let us understand the CNC. CNC is the machine used to design mechanical equipment by the combination of machine and computer (Software).

There are two main types of software used by the computer numerical control machine. One is CAM and the other is CAD. Moreover, it is used as antifriction guides ways to reduce fractions, improve the smoothness of fractions and reduce heat generation.

The first numerical control system was created by John T. Parsons. In the mid-1950s, while employed as a machinist at his father’s company, Parsons started developing inventive methods to create helicopter rotors for the developing aerospace industry.

The jobs of traditional machinists are progressively diminishing. Computer Numerical Control professionals are in high demand in the twenty-first century. The feeds and speeds calculations of CNC machines are discussed in this article.

How to Calculate Tapping Speed

Tapping is the process in which a thread is used to cut inside the hole so that the cap screw is threaded inside the hole. Moreover, it is also used to make holes in the nuts. To calculate the speed of tapping, the formula that is used is as under:

mm/min = RPM ÷ number of threads in millimeters

Proper tapping rate calculations are critical for achieving efficient tapping outcomes. The optimal speed for tapping is the greatest speed that the conditions allow while maintaining acceptable tool life.

Suggestion: 9 Best Quality Oil For High Mileage 5.3 Vortec Engine Review

As the length of the hole expands, the speeds must be lowered. Taps with tapered chamfers can work faster than taps with bottom chamfers. When compared to horizontal tapping, vertical tapping rates can be enhanced. If the lubricant is poor or the flow is restricted, the tapping speed can be reduced by using bottom lead or spiral flute taps.

Tread depth (%) is increased; it can lower the tapping speed. Moreover, if the thread pitch is coarse and taper threads are cut (50% of normal speed), this can also decrease the tapping speed.

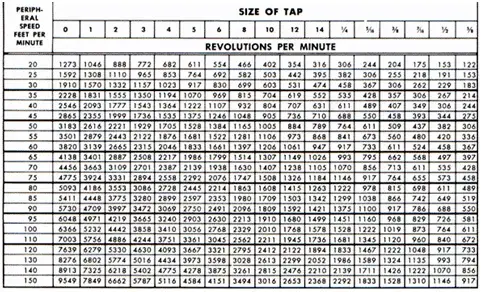

Tap Feed and Speed Chart

By changing the feed rate and the tap size the speed changes in revolution per minute. Following are the calculations for feed and speed within the chart.

How to Calculate Speeds and Feeds of CNC

There are two types of cutting speeds in the Computer Numerical Control machine. The imperial which is Surface Feet per Minute (SFM) and the metric which is Surface Meter per Minute (SMM) are two main types of cutting speeds.

Imperial Speed and Feed Calculation

The revolution per minute by imperial formula can be calculated by a formula which as:

RPM = 12 ⅹspeed(SFM))/(πⅹD(in)

The speed can be calculated by the formula:

Feed rate = RPM Ⅹ N Teeth Ⅹ Chip load (in)

Metric Speed and Feed Calculation

For the metric the revolution per minute can be calculated from the formula which is as under:

RPM= 1000 ⅹ speed(m/min))/(πⅹD(mm)

The speed can be calculated by the formula:

Feed rate = RPM Ⅹ N Teeth Ⅹ Chip load (mm)

RPM = Rotations per Minute, or the number of spindle revolutions per minute.

SFM stands for Imperial. Surface feet per minute, cutting speed, and tooltip speed through the material.

SMM stands for Metric. Surface meters per minute, cutting speed, and tooltip speed through the material.

Feed Rate = Inches per Minute or Millimeters per Minute, Feed Rate, Distance in inches or millimeters per minute the tool will go through the workpiece. N is the number of cutting teeth. CL stands for Chip Load per Tooth, which is the cutter’s progress per revolution for each cutting edge, otherwise known as the thickness of material taken by each tooth every rotation.

Popular For You: 8 Best Motor Oil For Cars Over 100K Miles For High Performance

Applications of CNC Machine

A Computer Numerical Control machine has a wide range of applications in the twenty-first century. The rapid-prototyping industry’s first major innovation was Computer Numerical Control machines. Prior to numerical control (used with punched tape tech) and computational numerical control (used with analog and digital computers), components had to be manually manufactured.

This usually resulted in bigger variations in final prototype items, which were exacerbated when machinery was manually utilized for full-scale manufacture. Moreover, many new Computer Numerical Control specialty machines are designed for specific production processes.

Electrochemical machining, for example, is used to cut very durable metal objects that would not be possible otherwise. Traditional Computer Numerical Control machines are better suited to and more commonly used for concept generation than production.

Frequently Asked Questions

At which feed rate does the CNC machine work perfectly?

It is recommended that the speed is normally set the RPM for the majority of the material that will be slicing on a CNC router between 12006 and 24008, then modify your feed rate to get the desired results.

What are the factors which are affecting the speed and feed of cutting?

In general, the substance being milled (steel, brass, tool steel, plastic, wood), the substance the cutter is constructed of (carbon steel, high-speed steel, carbide, ceramics), as well as the economic life of the cutter are all elements that impact the computation of cutting speed.